It is imperative that you use Grade 7 (or 4) nuts with B16 studs, because they have similar properties. ASTM A194 GRADE 4: These were taken out of ASTM A194 in 2017, but were heat treated molybdenum steel nuts.ASTM A194 GRADE 7: These are also heat-treated chrome-molybdenum steel nuts that are also suitable for sub-zero service conditions and have minimum Charpy impact values in accordance with ASTM specifications.There are two nut combinations you can use for B16 stud bolts.

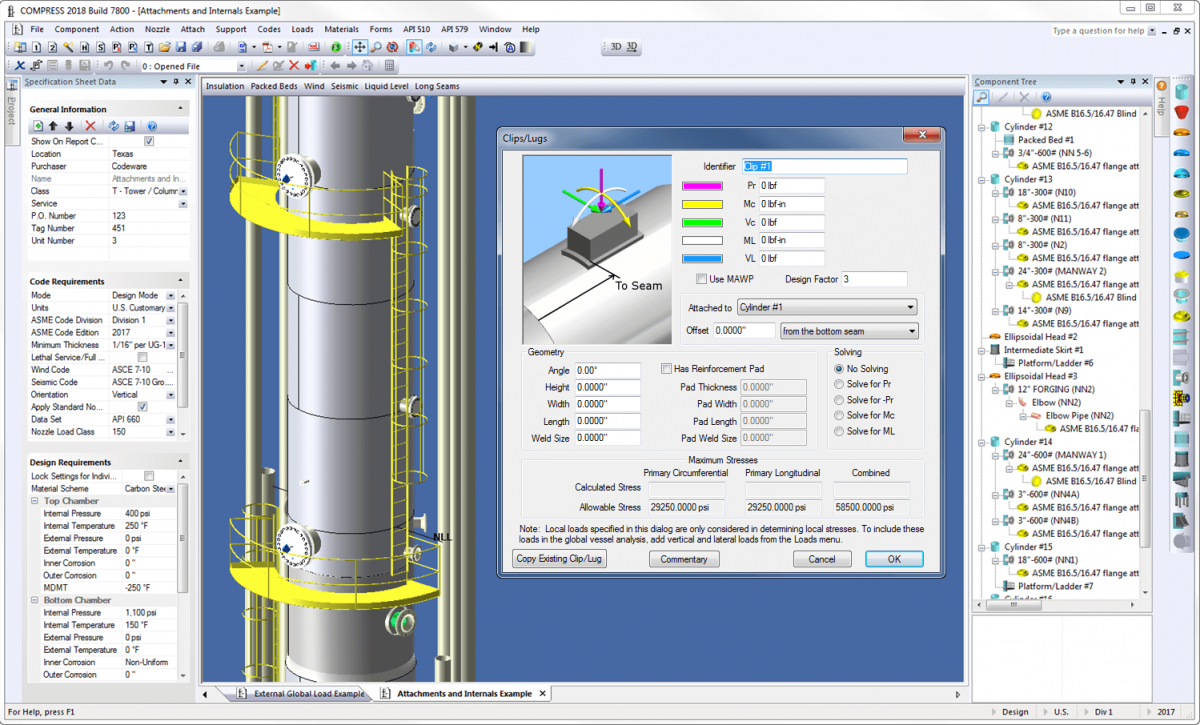

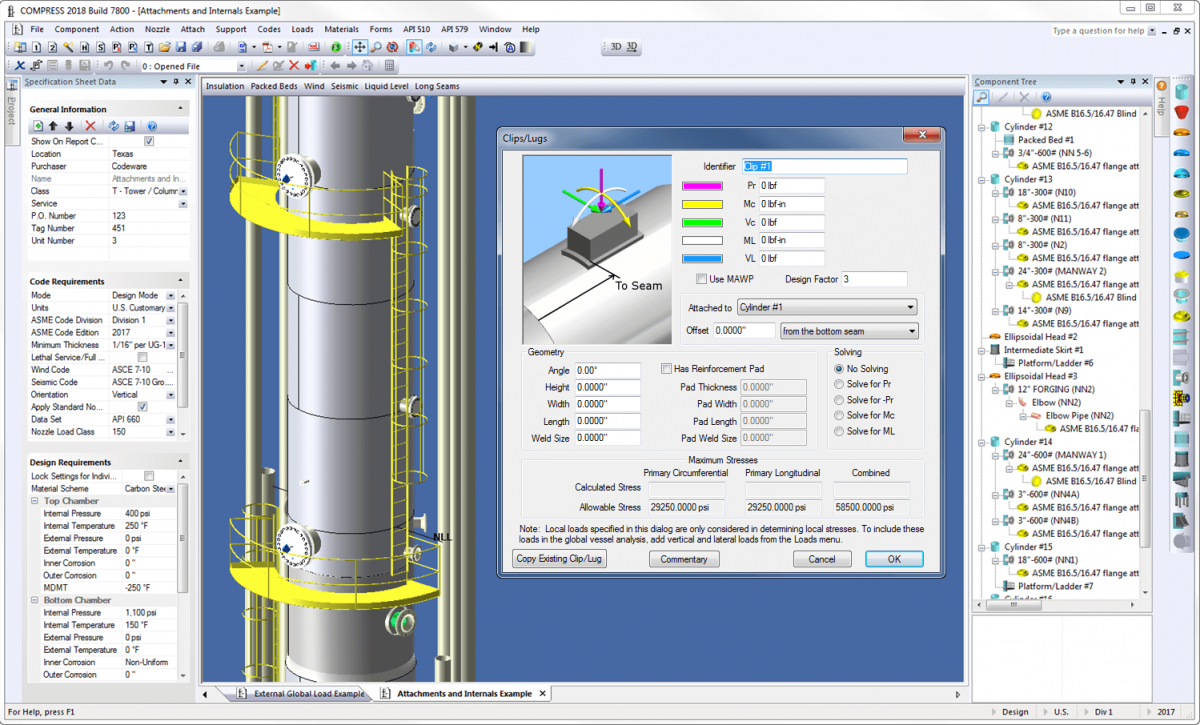

They are manufactured from a chromium-molybdenum-vanadium alloy steel,Īlthough A193 Grade B16 bolts and studs have similar strength requirements as Grade B7, the fasteners retain strength under high temperatures, and also experience less relaxation at those high temperatures. Grade B16 StudsĪSTM A193 B16 stud bolts are used primarily for high temperature applications of 751-1100F. We typically see Grade B7M bolts in hydrogen stress corrosion cracking (SCC) applications such as hydrofluoric acid or in Floating Head Heat Exchangers.ĪSTM A194 GRADE 2HM are similar to 2H nuts, except this grade is recommended for use in stress corrosion cracking environments. However, they have a lower tensile strength than B7 studs. Grade B7M Studs and NutsĪSTM A193 Grade B7M studs are identical in chemistry to Grade B7, as they are quenched and tempered carbon steel to achieve a lower hardness. NOTE: This does not include over tapping of the nut for coated materials as it would change the strength of the nut.ĢH nuts, also known as Heavy Hex Nuts, are very common in the industry and easy to procure. Therefore you should see failure on the stud before you see failure in the nut. Can you find the B16 mixed in? A194 Grade 2H NutsĢH nuts work in combination with B7 Studs and are stronger than the stud bolt. This is supposed to be a stack of B7s on a job site. The nut material for Grade B7 bolts is typically ASTM A194 heavy hex nuts (2H nuts).

4″ to 7″ inch stud bolts have an even lower yield strength of 75,000 PSI. Grade B7 fasteners with a stud diameter of 2-5/8″ to 4″ diameter have a lower yield strength of 95,000 PSI. ASTM A193 B7 stud bolts with a diameter of 2.5 inches or less will have a yield strength of 105,000 PSI. (See our article “ PTFE Coated Studs: Do They Work?” for more.) NOTE: Typically a coated stud will have a lower temperature rating than plain finish stud bolts. zinc plated and/or have a PTFE or Xylan coating for corrosion resistance. However, these bolts can have many different types of finishes, including: Grade B7 Stud Bolts are used in pressure vessels that do not need corrosion resistance, aren’t susceptible to stress corrosion cracking, and for temperatures typically less than 750F. The bolts are quenched and tempered (a.k.a heat treated) to develop the desired tensile strength (mechanical properties). Stud and Nut Combinations B7 Studs and 2H NutsĪSTM A193 Grade B7 bolts are made of chromium-molybdenum steel. NOTE: Items that we will not cover in this article include: coating practices such as zinc plated, PTFE or Xylan(R) coating, hex bolts, or hex cap screws or machine screw nuts and coupling nuts found in ASME B18.2.2, as these have nothing to do with industrial bolting. These nuts are intended for high-pressure or high-temperature service, or both.” ASTM A194: “This specification covers a variety of carbon, alloy, and martensitic and austenitic stainless steel nuts. ASTM A320: “This specification covers alloy steel bolting materials and bolting components for pressure vessels, valves, flanges, and fittings for low-temperature service.”. Ferritic steels shall be properly heat treated as best suits the high-temperature characteristics of each grade.” ASTM A193: “This specification covers alloy steel and stainless steel bolting material for pressure vessels, valves, flanges, and fittings for high temperature or high-pressure service, or other special-purpose applications. They are governed by three main industry standards: Industrial fasteners can be called stud bolts or - of course - just plain ol’ bolts. Summary of Standards for Common Fasteners heavy hex nuts (2H nuts, or Grade 4 & 7 nuts)īut we’ll start with an overview of the standards governing the use of nuts and bolts in industrial applications. In this article, we’ll discuss several different relevant aspects of these fasteners, including: The names also indicate which will perform better in certain environments, such as high-temperature and high-pressure applications.

At first glance, the names of fasteners used in bolting for ASME pressure vessels and piping can sound like something out of the old-school board game “ Battleship.”ī7, B8, 2H, A193.dangit, you just sunk my destroyer.Įach of these labels are meaningful, and can indicate the use of different materials (such as alloy steel or stainless steel) with different mechanical properties.

0 kommentar(er)

0 kommentar(er)